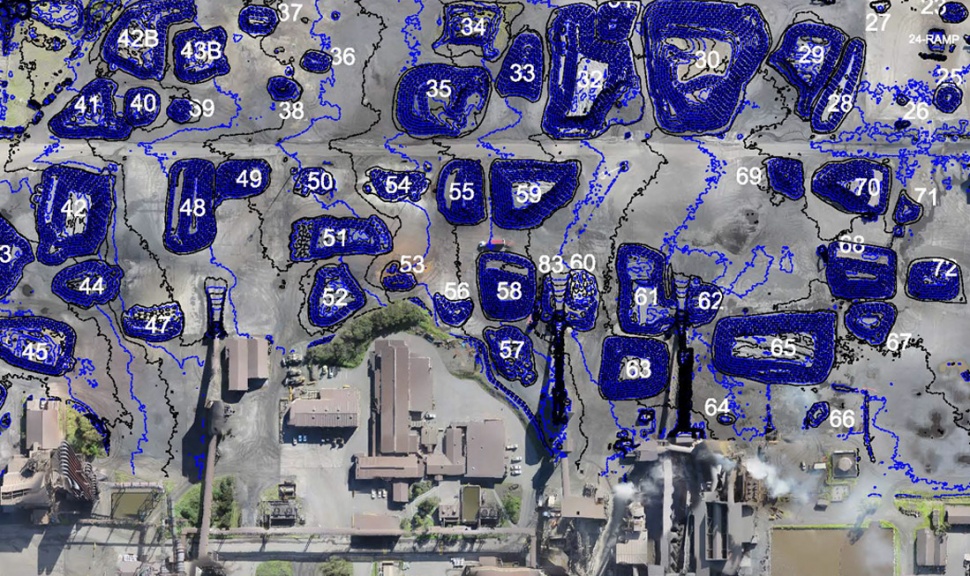

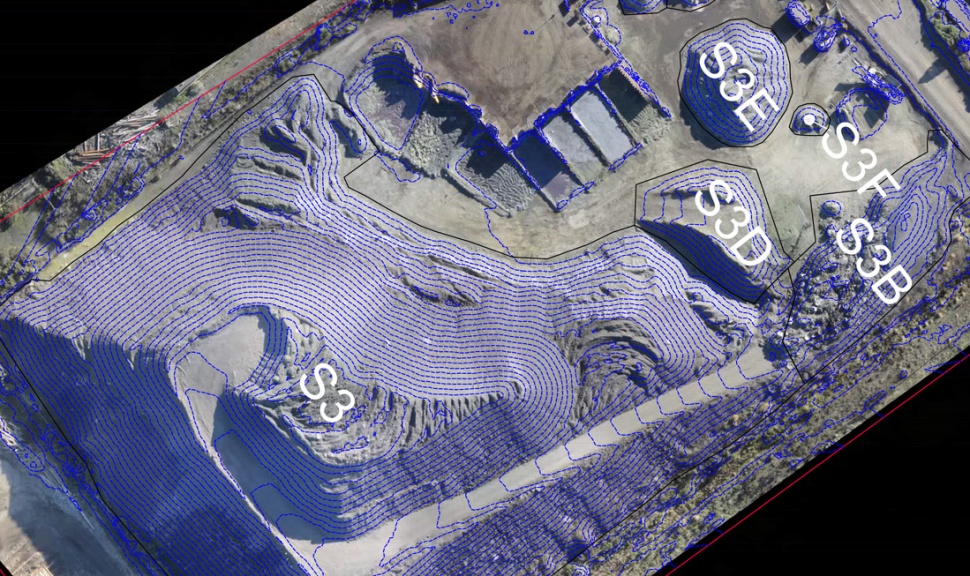

TEMCO Smelter Raw and Finished Product stock Pile survey

Location: Bell Bay | Tasmania

Status: Completed Yearly

Stock pile surveys have long been in the realm of the surveyor but times are changing and our methods too, have evolved. Big industry is tasked with cost saving in order to survive these difficult times and when $5 million dollars of product can sit in an individual stock pile, small percentages of accuracy can make a difference to both process methodology and cost margins.

In 2012 we were contacted to explore new methods of surveying stock piles at TEMCO’s George Town plant. Drone surveying technology has only recently arrived on the scene and we decided to embrace the new technology with astounding results.

New Occupational Health and Safety standards prevent access to the stock piles and revised internal accounting practices of the parent company required an unheard of calendar month turn around for this biannual survey.

Assigned with the job we developed a methodology and calculation process that has hit the target for two years running with proven results. Gone are the approximations of old, replaced by dynamic 3D stockpile models that can be reviewed and assessed for errors at will.

Historical data can be readily compared and processed to capture and improve the company knowledge of the density of the material within the stockpiles. Already, assumptions long held as being true are being questioned and paths for the company to save considerable money and resource are being identified.

It’s fair to say we continue to take stock of innovative and improved methods always searching for creative solutions and piles of results.

This project brought together 6ty˚ services including Surveying.